Digital manufacturing - Week SIX: Manufacturing Strategy

Author: Callum Baxter Date: 11/03/2023 Topic: Digital Design and Manufacture

Introduction

During the sixth teaching week I continued to learn the fundamentals of Siemens Plant Sim. This blog post will focus on how I developed a manufacturing strategy that informed my final simulation. My strategy will incorporate the Liquid-Crystal Magna to manufacture the phone cases, equipment to handle some of the post-processing and workers operating on rotating shifts to meet production demands. The aim of this strategy is to use takt time to establish shift patterns for workers and machinery requirements and use this information to project cost estimates for the annual production of 50,000 phone cases. These cost estimates will then be used assess the viability of my manufacturing strategy, assuming a revenue of £20 per phone case produced (as stipulated in week six’s production challenge brief).

Additive Manufacturing Requirements

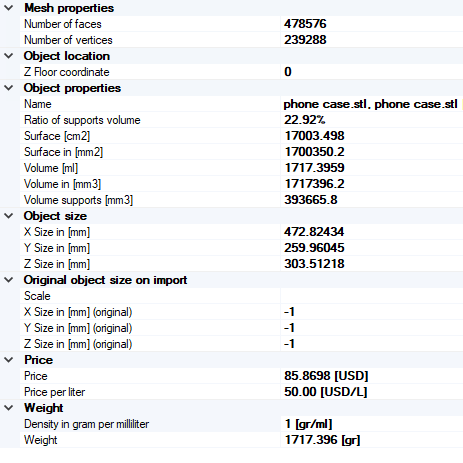

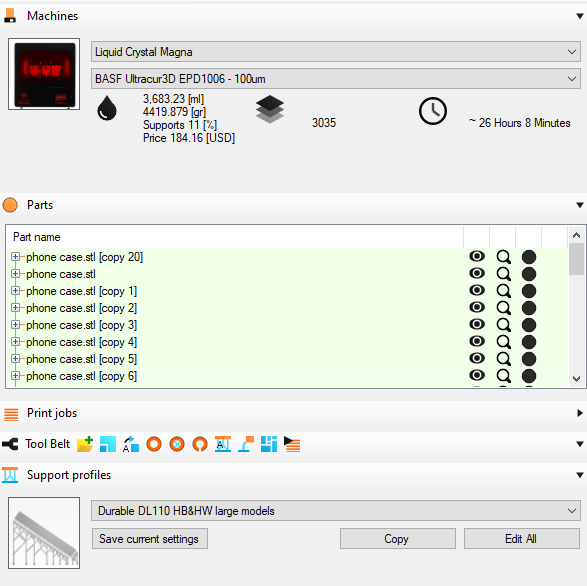

Further research revealed that the Liquid Crystal Magna has the capability to vertically stack parts within it’s build volume, vastly increasing the output of the printer (Fig.1). DLP production times are roughly proportional to the height of the active build volume and Figure 3 (below) shows the estimated build times and material consumption for the larger batch. As illustrated in Figure 3, the manufacture duration is 26 hours and 8 minutes, an increase of approximately 158% compared to the original production volume described in week four’s blog. Increased production results in increased waste material and each floor added to production contributes approximately 33.44% to material wastage, which costs around £51.90 per batch. However, this small cost in material and the increased production time is compensated by the increased output and reduced machinery requirements (stacking parts removes the need to buy additional printers).

As shown in Figure 3, doubling the output of the printer by stacking parts results in production output every 26 hours and 8 minutes. This means that 30 parts can be produced by a single printer every 2 days, and that twelve printers running simultaneously could meet the production target of 50,000 phone cases within one year with some accommodation for failures and setup. This time frame could be shortened by utilising more printers, however the brief does not require this and so I did not consider this as an option. The equation below shows how I calculated the printer requirements.

It is also important to note that prices for the LC Magna have increased since week four’s blog from ~£15,000 to £17,045. However, the cheap material and large batch size still make L-C Magna the most competitive choice for the mass-manufacture of the phone cases.

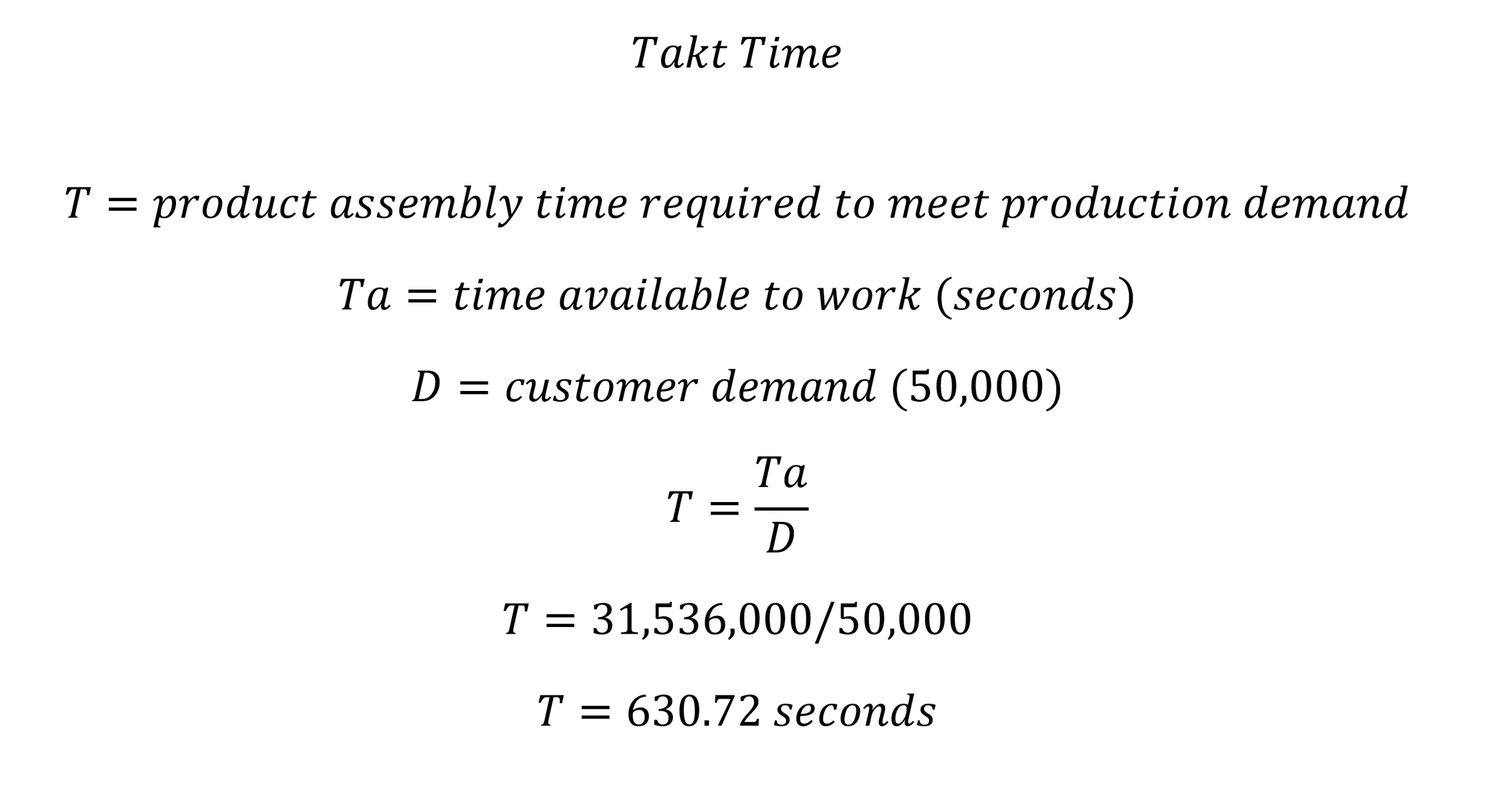

Therefore, in theory, a phone case needs to be produced every 630.72 seconds to meet the annual demand of 50,000 phone cases. The equation below expands upon my Takt Time calculation and presents a solution for calculating the number of LC Magna 3D printers required to meet the demand.

Post-Processing

After each batch is finished, build platforms from the printers need to placed within a wash tank to clean uncured resin from the surface of the phone cases. I decided to use the AirWash L produced by Photocentric for this production stage (figure 4). This is because the AirWash L is specifically designed to be used with the LC Magna and can accommodate the entire build platform without requiring operators to remove parts prior to being washed. Each batch of parts requires 16 minutes of washing within a specialised resin cleaner and then a further 4 minutes of washing within water. Therefore, two Air Wash L tanks are required per batch and the total wash time per batch is approximately 25 minutes (with accommodations for moving parts between the printer and the wash tanks). Using 6 AirWash L tanks (three filled with resin cleaner and three filled with water) would allow all of the build platforms to be washed within 2 hours before starting production again. This can be further expedited by having spare build platforms for each printer, allowing workers to immediately replace build platforms and start production again.

The parts then require curing under heat and UV light for 2 hours before supports can be removed. I chose to utilise the Photocentric Cure L2 (figure 5) to complete this process because, like the Air Wash L, it can accommodate an entire build platform without the need for workers to remove parts.

After curing is complete post-processing becomes more labour intensive. Support structures must be carefully removed and the surface of each phone case must be smoothed and polished. Supports with small touchpoints (~0.40mm) allow workers to easily remove supports without damaging the surface of the phones cases. Additionally, if supports are placed upon flat and accessible surfaces a worker could use jigs and a disk sander with a fine abrasive pad to quickly smooth any contact points left by removal of supports (figure 6). Therefore, it is important that the phone cases are sliced by an additive manufacturing professional that is aware of the post-processing techniques that are being used.

After the surface of each phone case is smoothed there are some further post-processing options that should be considered. Polishing can improve a customer facing surface and ceramic coatings, like those from Cerakote, can be applied to achieve a smooth and uniform coloured finish (figure 7) (FormLabs, 2023). Each of these processes add complexity and cost but add to the quality of the finished product.

shift patterns

Two workers are required to work three days every week, one would work Monday-Wednesday, the other Thursday-Saturday. Table 1 (below) shows an example of the activities within the worker’s shift patterns and Table 2 shows the weekly manufacturing timetable across the six working days.

It is important to note that ceramic coatings require 5 days to fully cure before they can shipped to clients. Therefore there would be a delay of around 5 days between completing all post production processes and packaging/shipping finished products.

Table 1: Weekly operations timetable for production workers

Table 2: Additive manufacturing timetable. Yellow bars show the 27 hour production time (rounded up) that overlaps two workdays (red sections). 3 manufacturing cycles would be spread over 6 working days (Mon-Sat).

Conclusion

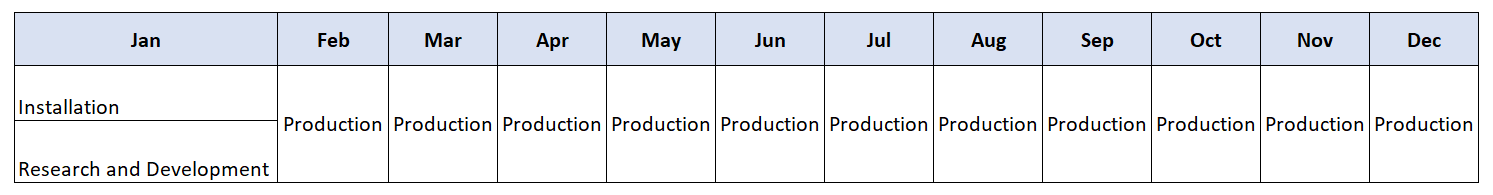

Assuming production begins in January and the manufacturing plant is not decommissioned once manufacturing has concluded, Table 3 (below) shows the production timeline necessary to meet the production target of 50,000 phones case within one year. This timeline takes into consideration machinery installation and setup, research and development, production and worker shift patterns and activities. January is used to install all the necessary machinery and to test different slicing and post- processing methods before production begins in February and concludes in December.

Table 3: Annual production timetable

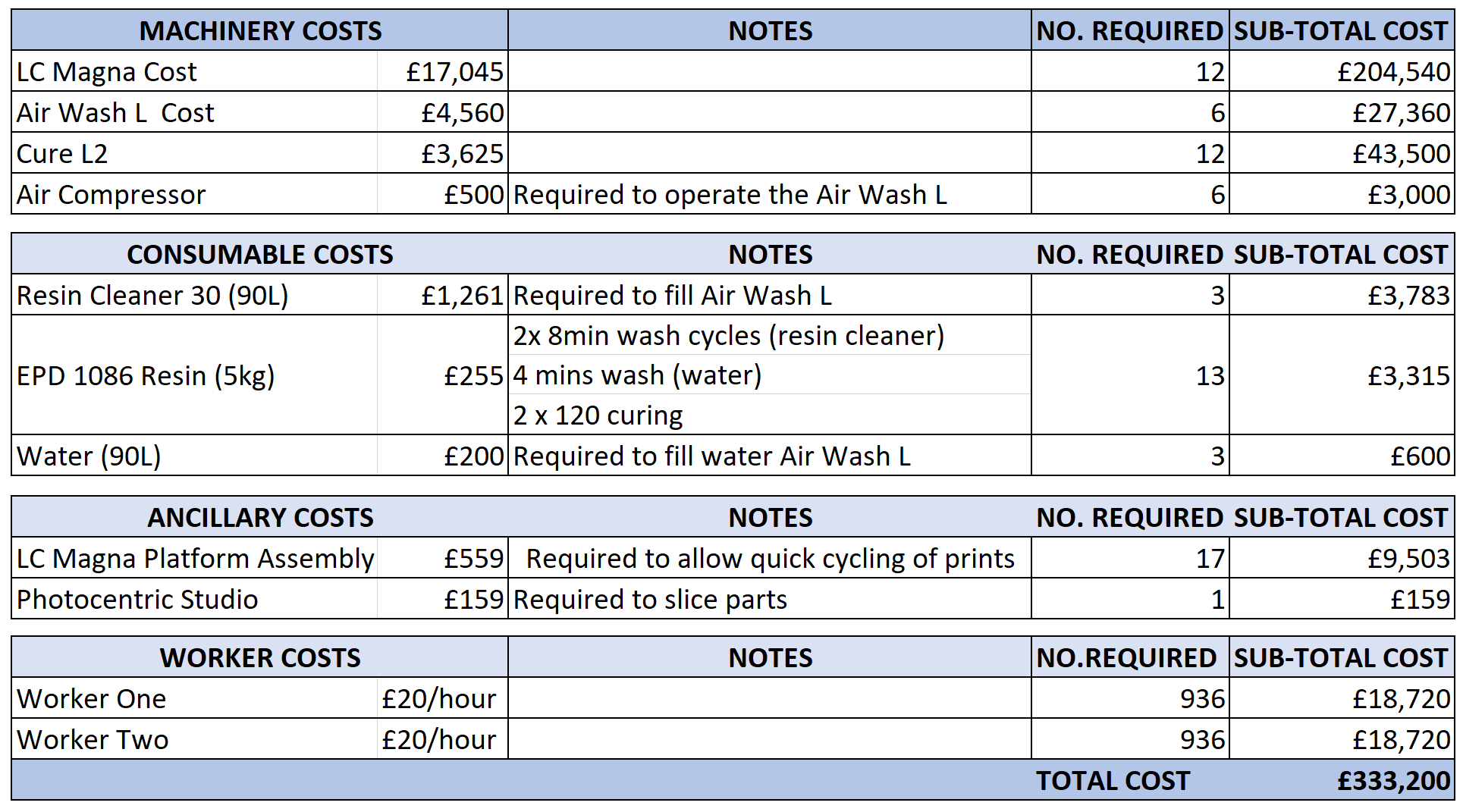

Table 4 shows the costs associated with purchasing the machinery required to meet the production target. As illustrated in table 4, approximately ~£334,000 will be spent in installing and operating the manufacturing facility. Therefore, even with a large budget set aside for maintenance costs and ceramic coatings, this manufacturing strategy is viable when it is assumed there will be a revenue of £20 per phone case produced (£1,000,000 annual revenue).

Table 4: Installation and operation costs

Appendix

REFERENCES

Cerakote. (no date) Cerakote Homepage. Cerakote. [Online] [11/03/2023] https://www.cerakote.co.uk/

FormLabs. (2023) Guide to Cerakote Ceramic Coating for SLA and SLS 3D Printed Parts. FormLabs. [Online] [11/03/2023] https://formlabs.com/blog/ceramic-coating-3d-printed-parts/

Incra. (2023) Incra Build It Starter Kit Manual. Incra. [Online] [11/03/2023] https://incra.com/manuals/build-it_starterkit_manual.pdf

Photocentric. (no date) Photocentrc Air Wash L. [Online image] [11/03/2023] https://photocentricgroup.com/3d-printing-post-processing/

Photocentric. (no date) Photocentric Air Wash L Technical Specifications. Photocentric. [Online] [11/03/2023] Photocentric-Air-Wash-L-Technical-Specifications.pdf (photocentricgroup.com)

Photocentric. (no date) Photocentric Cure L2. [Online image] [11/03/2023] https://photocentricgroup.com/3d-printing-post-processing/

Photocentric. (no date) User Manual. Photocentric. [Online] [11/03/2023] Photocentric-Studio-User-Manual-V1.0.3.4.pdf (photocentricgroup.com)