DIGITAL MANUFACTURING - WEEK TEN: SIEMENS MINDSPHERE

Author: Callum Baxter Date: 02/05/2023 Topic: Digital Design and Manufacture

INTRODUCTION

During the tenth teaching week Siemens Mindsphere and Siemens Digital Factory was used to analyse the process duration of each of the six stations within the Festo Cyber-Physical Lab. This involved changing the original digital twin to incorporate the siemens Mindsphere library and Mindsphere interface so that the simulation could connect to the Siemens Digital Factory application.

Siemens Digital Factory

The Siemens Insights Hub is an Industrial Internet of Things interface. Within the Insights Hub is an application called ‘Digital Factory’. This application enables users to collect data from real world processes and feed it back into their digital twin simulations. Informing digital twin simulations in this way can enable manufacturing professionals to gain an intimate understanding of the capabilities of their equipment, better plan for maintenance/ downtime, and understand how to optimise their production lines.

During it’s operation, the Festo CP Lab collects and stores data in the cloud which can be used to inform digital twin simulations. This week’s class aimed to teach the process involved with recalling and utilising the process time data of each of the six stations within the Festo Cyber-Physical Lab. Using the data from the Cyber-Physical Lab allows the comparison of the process time estimations made during Week Seven’s Blog and the actual process times (below). The Mindsphere data was taken from 24th March 2023 from 11:01:00 to 11:20:00. However, this data only provides a general overview of each of the station’s process times and does not take into account factors such as human error and failure rates (especially when considering the Pick-by Light station and Pressing Station).

Figure 1 (Left): Mindsphere process time study screenshot. Figure 2 (Above): Comparison of video time data and Mindsphere process time data.

IMPORTING DATA INTO SIEMENS PLANT SIM

Importing data from Mindsphere into Plant Sim requires the use of the Mindsphere Library. This library gives the user access to the Mindsphere interface object, which can be integrated within the digital twin model, as shown in figure 3. This object enables Plant Sim to connect to the Siemens Insights Hub and the Digital Factory Application.

Figure 3: Mindsphere Interface object integrated within the Festo CP Lab (assembly line) digital twin model.

Using Siemens Digital Factory each station within the simulated Festo CP Lab can be mapped to a recipe that calculates the real-world processing time of that station. This is done using data collected from a period of time specified by the user. Figure 1 (above) shows the data used. Once this data is loaded into Siemens Plant Sim via the Mindsphere interface object each of the stations within the simulated Festo CP lab will have their process times changed to match that of the calculated data (as shown below).

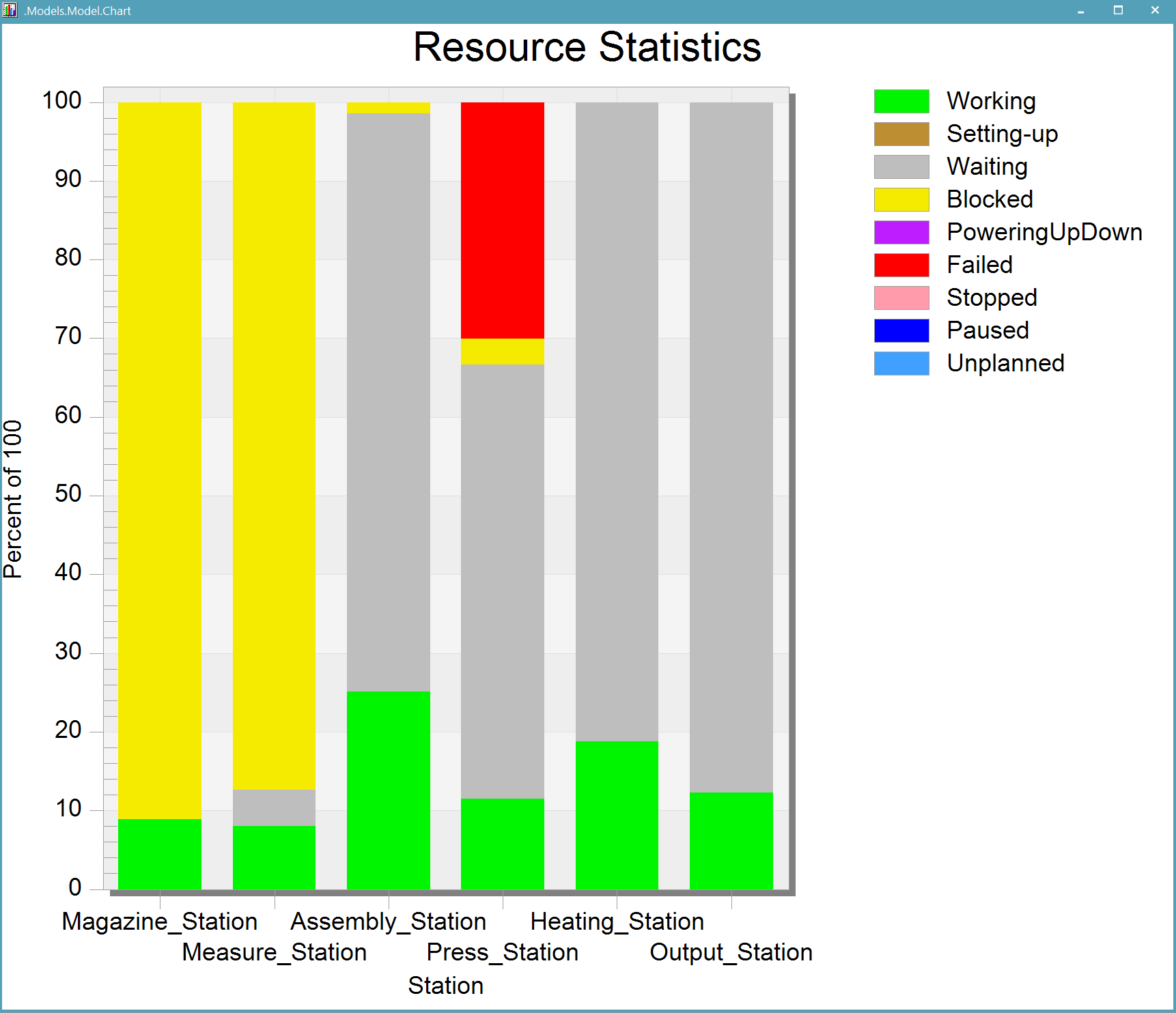

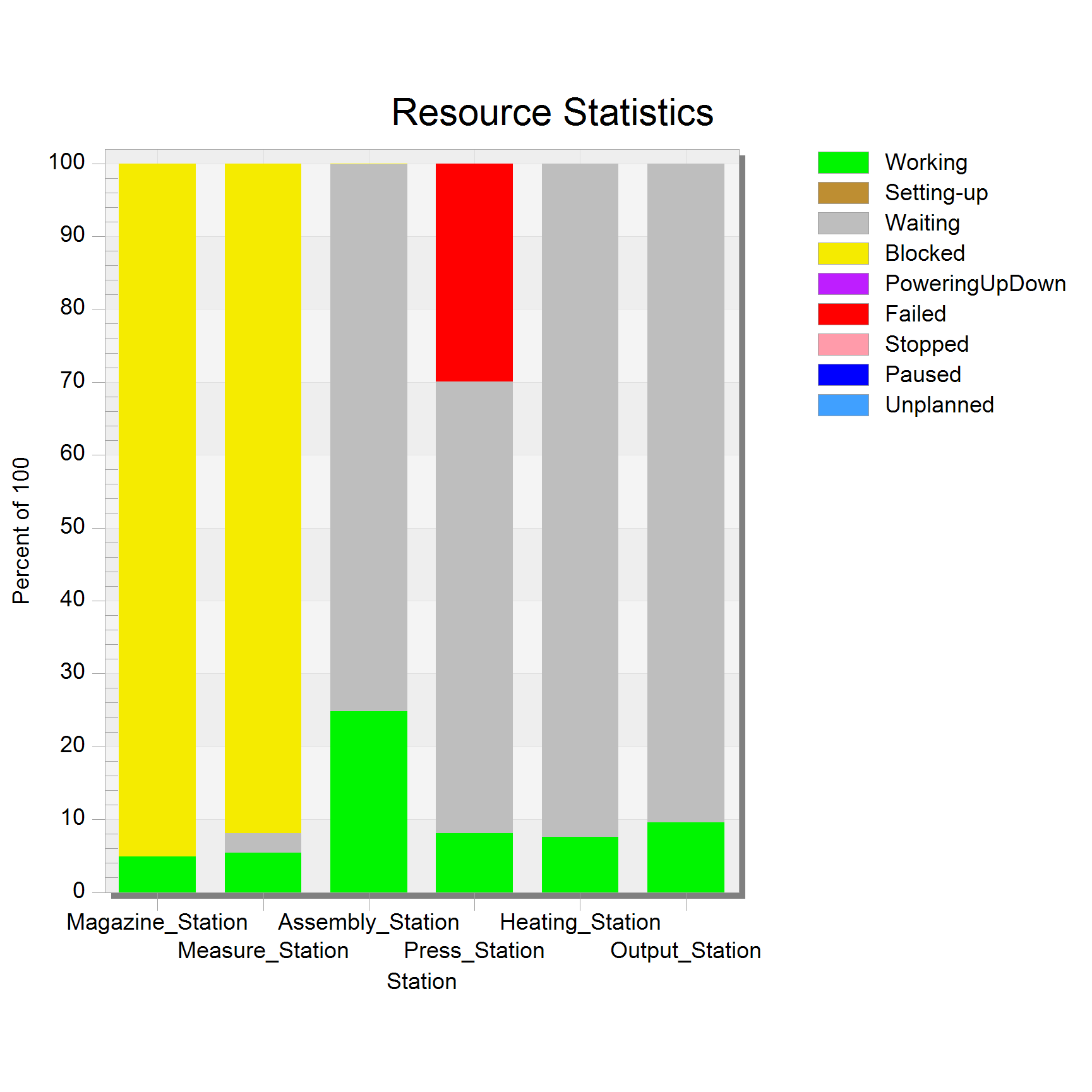

Once this data has been correctly imported, simulations and bottleneck analyses can be run as normal. The images below show the results from a bottleneck analysis based upon the new imported data. When compared to the original bottleneck analysis, it can be seen that a bottleneck remains at the Assembly Station due to its long processing time. In reality it is important to note that this station would also present a bottleneck due to the presence of human error. If this station was automated it would become more efficient. Figure 10 also shows how there is a small bottle neck at the Heating Station too, which was not present in the original analysis. This illustrates how using real world data can present a manufacturing engineer with a more accurate simulation and provide better insight into the capabilities and limitations of an existing production line. This weeks coursework activitites concluded once the simulation was connected to Mindsphere and a bottleneck analysis was conducted.

Figure 10: Bottleneck Analysis using imported Digital Twin data.

Figure 11: Original bottleneck analysis from week seven’s blog.

Figure 12: Bottleneck Analysis

The button below will download a version of the Festo assembly line that is connected to Siemens Mindsphere. This file can only be viewed within Siemens plant sim.

REFERENCES

No information was referenced within this blog post.