Digital Manufacturing - Week Two: PFMEA Analysis

Author: Callum Baxter Date: 16/02/2023 Topic: Digital Design and Manufacture

INtroduction

Process Failure Mode and Effect Analysis (PFMEA) is used within manufacturing and engineering industries to predict potential failures within production systems before they occur. It is typically used in the early stages of product development to prevent issues associated with production and to improve product quality. PFMEA can be a useful tool that helps to identify inefficient production systems and develop risk mitigation strategies.

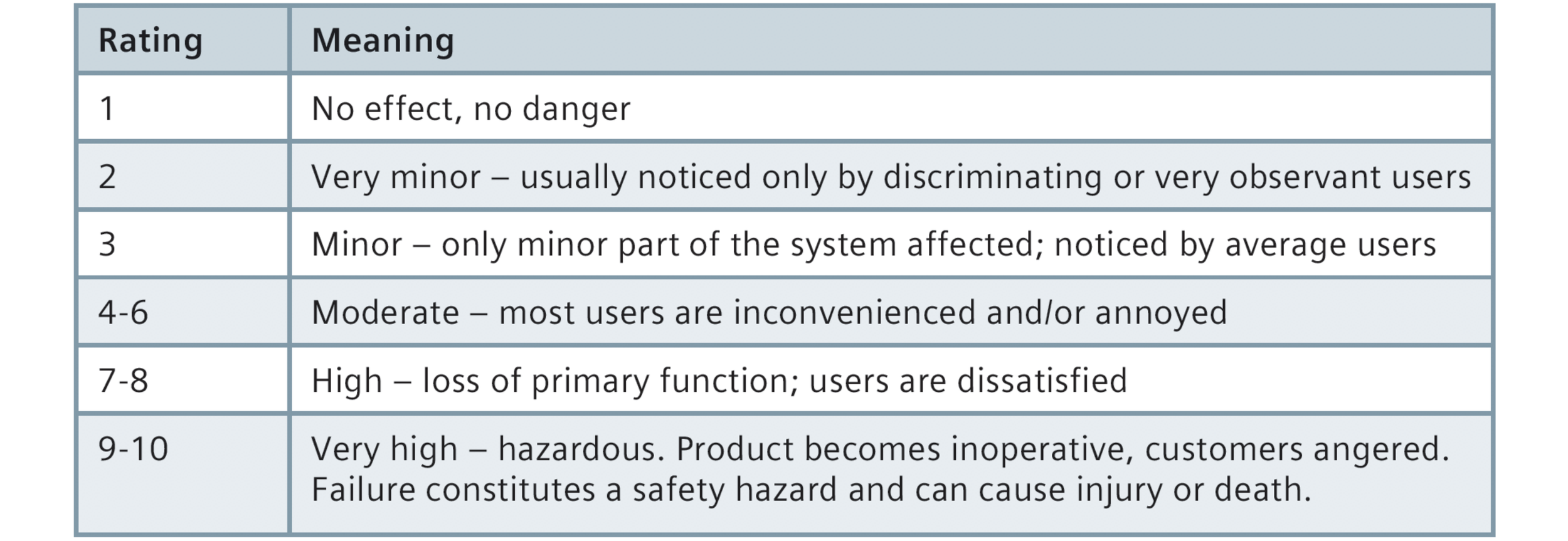

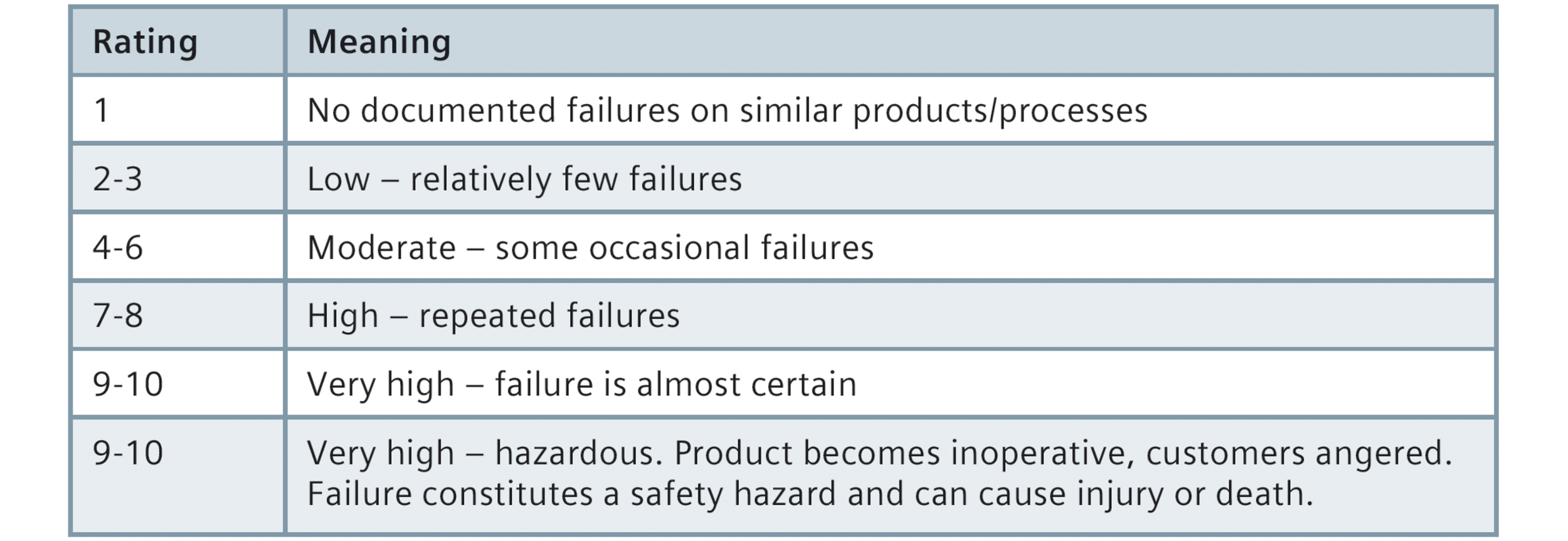

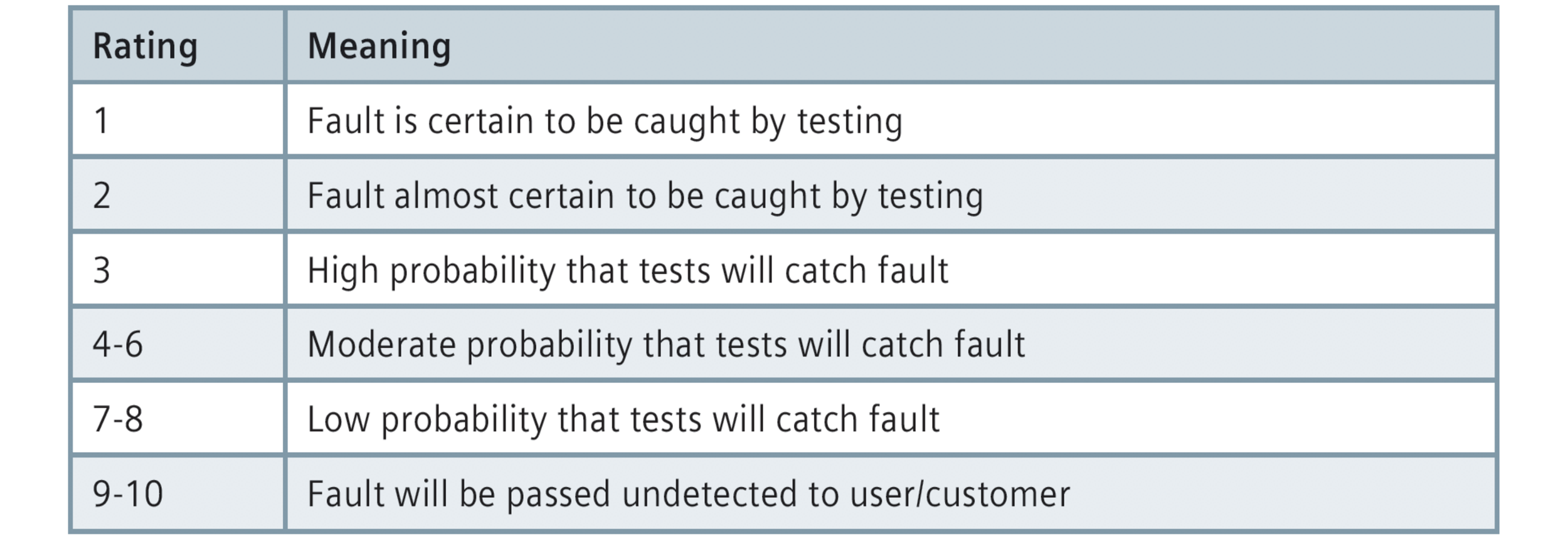

PFMEA measures three criteria and scores each criteria from 1-10. Tables 1-3 show the scoring metric for each risk criteria. These scores are multiplied to generate a Risk Priority Number (RPN) which can be used to measure the effects of risks if they were to occur. The three criteria that are measured when generating a Risk Priority Number are:

SEVERITY. The severity of a failure if it were to occur. How many people/ processes will be effected? In what way will those people/processes be effected? For how long will those people/ processes be effected?

OCCURANCE. How likely is it that this risk will occur? How often will the risk occur?

DETECTION. How easy is it to spot this failure? How long could it go undetected before it becomes an issue?

It is important to professionally judge and score each risk accurately so that risks can then be prioritised and mitigated accordingly. This is because risks with similar scores will be harder to prioritise. Within an industrial setting, receiving professional advice from relevant experts is advised.

Professional Guidance - Siemens

Below is a guidance document and tables published by Siemens. They describe how to conduct an accurate and professional Failure Modes and Effects Analysis and the scoring metric for each risk criteria. This documents was used as a reference during this weeks workshop session (15/02/2023) and when conducting my own PFMEA.

Table 1: Severity Scoring Metric (Siemens, 2016)

Table 2: Occurence Scoring Metric (Siemens, 2016)

Table 3: Detection Scoring Metric (Siemens, 2016)

PFMEA - Festo Cyber-Physical Production Line

Below is a PFMEA study for each stage of the Festo Cyber Physical production line. Alternatively, the full PFMEA can be downloaded by clicking the ‘Download’ button below.

REFERENCES

Siemens. (2016) How to conduct a failure modes and effects analysis (FMEA). Siemens. [Online] [16/02/2023] https://drive.google.com/viewerng/viewer?url=https://polarion.plm.automation.siemens.com/hubfs/Docs/Guides_and_Manuals/Siemens-PLM-Polarion-How-to-conduct-a-failure-modes-and-effects-analysis-FMEA-wp-60071-A3.pdf&wmode=opaque